In India there is so much variations in temperature in different parts from south to north and east to west. Delhi is the capital of India and it is the political city as well as it has the major industries there so there is always requirement of Acoustic insulation in every building as walls in general these are built with elements heavier than the partitions between different dwellings, they can be considered as already suitable for obtaining an evaluation index of soundproofing power higher.

|

| twigafiber |

It will therefore be sufficient to fill the inter space with self-supporting panels. Acoustic insulation is the chief method for controlling sound propagation in buildings in cities like Delhi. In particular, acoustic insulation has the job of reducing noise transmission between two premises.

Acoustic Insulation also known as Soundproofing, that is any means of reducing intensity of sound, sound pressure with respect to a specified sound source and receptor. This is required for reducing Sound Abuse. This is mainly for providing comforts and cozy working atmosphere. The main application is on Buildings, Malls, Theaters, Offices, Hotels, Studios and Hospitals where simultaneous activities are going on.

There Are Several Basic Approaches to Reducing Sound:

- increasing the distance between source and receiver

- using damping structures such as sound baffles

- using active anti noise sound generators.

- using noise barriers to reflect or absorb the energy of the sound waves

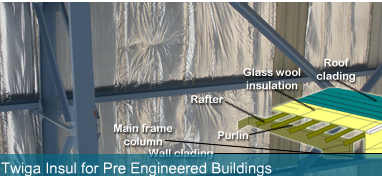

An energy efficient building envelope contains both a thermal barrier and an air barrier. The key to an effective thermal barrier is proper installation of quality acoustic insulation products. In Delhi, which is the heart of India is lack of land to make houses so there is only option is to have townships for people where the Acoustic insulation plays an important role. A house should have a continuous layer of Acoustic Insulation Delhi around the entire building envelope.

Some types of acoustic insulation reduce air leakage. Another effective method, particularly for very rigid walls, is to use the diaphragm effect. This consists of filling the cavity with a material comprising a thin

membrane with very low effect.

|

| twigafiber |

- Acoustic insulation is used in ceilings, floors and refurbishing walls.

- Acoustic insulation is used in lightweight metal or wooden, roofs and floors.

- Acoustic insulation includes in drainpipes, conducts, engines.

- Damping of metallic structures.

- Acoustic insulation is used for gypsum board partitions and ceilings, metal panels.

- Sealing of joints and overlaps.

- Acoustic insulation is used for Cavity walls.